The longevity of Nanophase polishing slurries reduces processing cost by increasing the number of optics you can produce when compared to other polishing slurries, and reducing the time required to achieve your desired surface finish.

Manufactured with a proprietary plasma process, our Cerium Oxide particles are discrete single crystals that are nonporous and at near theoretical density, which means they do not change shape or density during a polishing operation. This, combined with our specially designed additives, results in longer slurry life and extend production on your polishing machines.

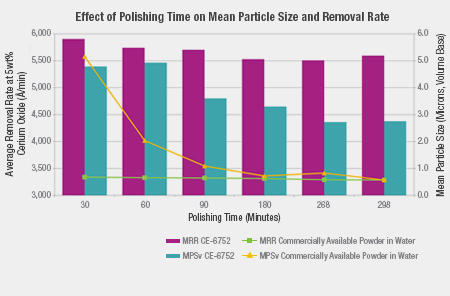

Tests run in our Polishing Applications Support Lab found that standard ceria attrits down during the polishing process, while Nanophase Ceria's particle integrity results in consistent, high removal rates and improved ROI.

Nanophase is a Proud Member of APOMA

American Precision Optics Manufacturers Association