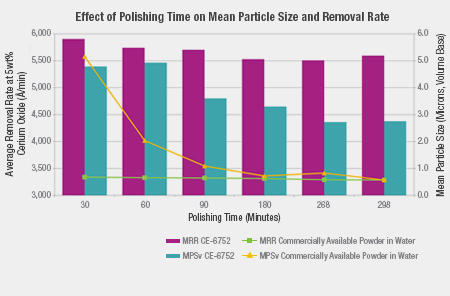

Nanophase optical surface polishing slurries offer more consistent polishing than other commercially available slurries. Our proprietary plasma process produces highly dense and fully stable nanoparticles that don't break down during polishing. Not only do they produce the same results each time they are used, but the slurry does not need to be topped off as is required with most commercial slurries.

Nanophase Cerium Oxide improves upon the fundamental performance requirements of optical surface polishing slurries across the board: improved flatness and roughness, faster time to surface finish and improved surface quality. In addition, the use of Nanophase slurries leads to reduced waste and defectivity and improvies ROI no matter what material you are polishing.

Our slurries will also expand your capabilities, allowing you to meet more rigorous specs in an increasingly demanding industry.

Learn more about Nanophase Slurry Technology ROI: Results, Consistency, Productivity, and Opportunity

Our cutting edge Optical Polishing Application Development and Customer Support Lab ensures that we provide the precise particle distribution necessary, while monitoring the process-related factors that impact the performance of our Cerium Oxide slurry.

Nanophase is a Proud Member of APOMA

American Precision Optics Manufacturers Association